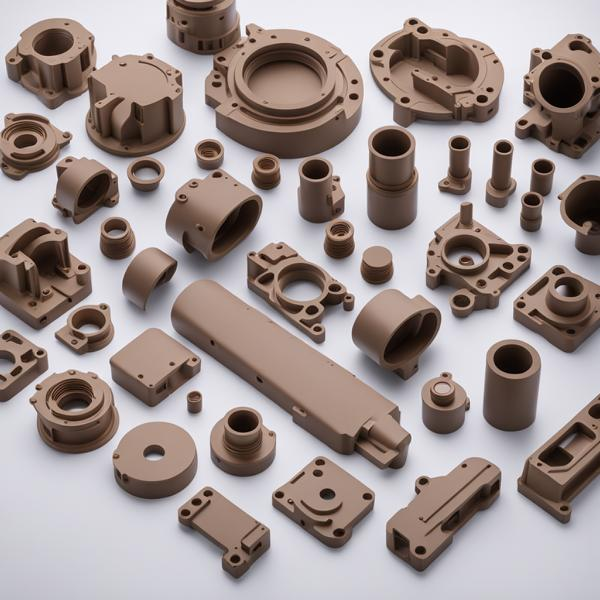

Specialized PEEK (Polyetheretherketone) injection molding services for creating high-performance plastic parts with exceptional mechanical strength, chemical resistance, and thermal stability for demanding applications.

High-temperature injection molding with precision control for optimal part quality

Advanced manufacturing capabilities for high-performance PEEK components

Specialized equipment for PEEK's high melting point (343°C)

Advanced mold design optimized for PEEK characteristics

Comprehensive quality assurance throughout the process

Tailored PEEK formulations for specific applications

Specialized process steps for optimal PEEK part production

Careful drying and preparation of PEEK pellets

High-temperature melting and homogenization

Precise injection with optimized pressure control

Controlled cooling for optimal crystallinity

Comprehensive range of PEEK formulations for various applications

PEEK injection molded parts serve critical applications across multiple industries

High-performance components for extreme environments

Biocompatible solutions for healthcare applications

Ultra-pure components for sensitive processes

Reliable components for harsh environments

Key benefits that make PEEK injection molding the preferred choice

Exceptional mechanical and thermal properties

Resistance to harsh chemicals and environments

Maintains properties at high temperatures

Complex geometries and precise tolerances

Comprehensive quality assurance for PEEK injection molded parts

Common questions about PEEK injection molding

Get expert PEEK injection molding services with exceptional quality and precision. Contact us today for a custom quote.

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.